Overhead line fittings mechanically provides the interface for electrical connections and securing insulators and conductors within place.

Fittings for different conductors are designed for the termination, suspension, or joining of the conductors, and are directly attached to the conductors. Dead-end clamps, suspension, branch-off clamps, connectors, bundle spacers, and vibration protection fittings are included in this category.

These overhead lines are required for insulating these utilities from touching the ground and also for ensuring that vehicles or people do not interrupt them or get affected by them. Owing to the fact that these overhead lines ensure the safety of the people and also insulate various overhead utilities, they need to be made from materials that are durable and strong.

This is mainly used on the utility pole, light pole and power pole. & is made of premium angle steel.

It is physically strong & has high tensional strength, which allows it to remain strong regardless of the mechanical forces that can subject it to tensile strain.

It is hot dip galvanized so that it is free from chemical damage that can be caused by water and other corrosive fumes.

The lengths of the alley arms vary between 60, 84 and 120 inches of alley arms. In terms of the design, this pole attachment hardware is designed to be installed on either the left or right side of the power pole. Another distinct design feature of the alley arm is both its ends are beta closed. This means that when installed, the angle narrows down to zero. Allay arms are designed to be installed with the off-side steel cross arm before the two are fixed to the pole. This ensures that the steel cross arm is supported firmly.

Pinnacle Engineering designs and manufactures quality arm brace for the pole line. We ensure that our electrical pole accessories undergo vigorous tests before they are supplied to the market

It connects the socket insulator by its ball.

The hot dip galvanized Ball clevis comes in different shapes and designs. One of the designs that you may consider buying is Y clevis. Its name is because it has a “Y” design and on one side of it, there is a ball.

Cast iron is the main material that is used for making the ball clevis & its tension strength is tested to ensure it is more than 45 kn.

We are a reliable ball clevis manufacturer in India and we will strive to meet your demands.

Pinnacle Engineering is a leading cable suspension clamp manufacturer in India, which is used to secure cable, cable bundles, and cable strands.

It allows the conductors to be suspended at different angles and positions.

The main components of a suspension clamp include the body, cable attachment cable clamp mount, straps, washers, and cable spring cable suspension cable clamp. Cable suspensions can be mounted horizontally or vertically depending on the needs of the application.

This cable connection is made using cable tie wire wrap or in some cases screws. Cable clamps are available in three types. These are street line type, angled type, and C cable serpentine type.

These cable suspensions are used in the electrical power generation and transmission industry in applications such as underground or onshore oil & gas pipelines, oil drilling platforms, wind, and solar farms, among others.

The cross arm braces are suitably designed to work perfectly in the telecommunication industry, power transmission lines & railroads.

These are perfect for both tangent and dead-end applications & allows to give the conductors on the transmission lines adequate support. They are also meant to anchor the conductor lines at for stability.

The crossarm braces are made of carbon steel, making them durable and highly reliable, with proper Galvanizing. It has a smooth and rounded end, which allows them to complement the conductors in various applications. They also come in different lengths which are 20, 26, 28 and 32. The thickness of the brace is 1/4 inches. One end of the hole measures 9/16 while the other end is 7/16.

It exists as a single piece hence is not a product of the welding process. The compactness and quality of the material of this crossarm brace are responsible for its massive tensile strength. The tensile strength of these braces ranges between 410N/mm2 to 560N/mm2

Crossarm pins are components of cross arms in transmission line systems.

The structure that holds and supports the overhead power lines, is called crossarms. Crossarm pins are used to hold crossarms together while preventing them from moving.

Crossarm pins are mainly used in transmission lines. It is used to connect crossarms, thereby joining the crossarms. By joining crossarms together, they are made stronger and more resistant to vibration.

They join two crossarms or a cross arm with an insulator mounted on it. It is also put into one crossarm for joining cross arms together.

The cross arm pins have three parts – the crossarm pin base, a crossarm pin body, and the crossarm pinhead. The cross-arm pin base is fitted in an opening of a cross arm.

An electrical cross arm is a strong and efficient pole hardware fittings that are used for supporting conductors in a power transmission line.

It is made up of steel due to its tensile strength & hot deep galvanized, which prevents rust, corrosion, and abrasion.

Steel is the right choice of material for the electrical cross arm due to its tensile strength. It can sustain the mechanical forces which may threaten its stability.

The electrical cross arm comes in five different configurations. These are the Power pole cross arm, Line-cross arms, Telephone pole cross arms, and Side arms. Each configuration is specifically designed to work well in its application

The hot line clamp is a metal structure that insulates current from high voltage transmission lines to the transformer. The aluminium body works either as a permanent or temporary fixture to connect conductors by using the keeper and eyebolt to secure and maintain a constant pressure as a reliable fixture to attach to hotlines.

The hot line clamp tap is specially designed for distribution tap connections and provides good corrosion resistance.

Features

Minimal conductor cold flow

A lashing wire clamp is also called a cable lashing clamp, there are two types;D lashing wire clamp and E lashing wire clamp. The lashing wire clamp is used in building, mostly aerial construction, to secure lashing wire which is terminating or to hold the ground wire to a separate strand. This is an important safety feature when used in construction. The lashing wire clamp is made from stainless steel and is composed of a stud, two washers, and two bug nuts.

The strength of the lashing wire clamp jaws is more than 50,000 PSI. This makes the safety features of the product even better, as you can be sure the clamp jaws will not come undone when securing the lashing wire. This also minimizes damage to the cables.

Lashing clamps ensure bug nuts are tightened and the lashing wire itself is terminated properly. Terminating lashing wires stops them from breaking, which would result in poor connection, injury, or damage to the entire span of the lashing wire.

Key Features:

Sold in 100-piece cartons

Parallel Groove Clamp is often required to install a second conductor in a closed loop. It comprises of two components, the upper part, and the lower side. They are drawn together to exert the clamping force on the transmission line. This can be a power line or a telecommunication cable.

It is made of heavy-duty aluminum which is strong and resistant to various forms of chemical and physical damage. The aluminum metal also provides takes the excessive clamping force that is required when clamping parallel conductors. It also provides resistance to UV-rays.

The parallel groove conductors feature a ‘precise fit’ design. This allows it to be clamped accurately and offer the desired support. The design also allows the clamp to support different conductor sizes. The parallel groove provides a platform onto which the conductor will rest.

Features

Pole top bracket hardware accessory is used for mounting line post insulators onto the desired positions. This needs to be done to create a significant separation distance in the middle phase.

It is made of hot dip galvanized carbon steel. The tension strength of our pole top bracket can be as high as 70kn.

In terms of the design, a typical pole top bracket is designed to allow the mounting of the wood poles which is done using bolts. So, the spacing of the bolts needs to be well-defined. Normally, there are two diameters on the pole top bracket and they are spaced center to center.

It is usually used in conjunction with the pin insulator. It is specifically designed to support the insulator on top of the pole.

A pole top pin is made up of hot dip galvanized steel & is usually supported to the pole with the help of bolts. These bolts ensure that the insulating units are well-secured. It surpasses the minimum load both traversal and longitudinally.

It is also important to note that pole top pins come in different sizes in terms of length. This automatically means that some of these overhead power fittings are longer than others.

A socket clevis referred also as sock tongue, & is perfectly designed to complete the connection between socket clamp and socket type insulator.

When it comes to size, this socket clevis is designed to fit around conductors of different sizes. Socket clevis is quite versatile hence can work with any type of overhead conductor.

Our socket clevis for sale is made from cast iron material & hot dip galvanised.

Stay rod also known as stay set, is used for connecting the stay wire to the ground anchor. It ensures that the wire is firmly rooted to the ground and everything remains stable.

There are two types of stay rod, namely bow stay rod and the tubular stay rod. It is made up of high-grade galvanized stainless steel.

Tubular stay rod is adjustable through its turnbuckle. On the other hand, bow type stay rod is further divided into different categories which include stay thimble, stay rod and stay plate.The stay rod also has a high tensile strength which keeps it intact from mechanical forces.

A suspension clamp is designed to give the conductors both physical and mechanical support. It enhances the stability of the conductor by limiting their movements especially against a strong wind, storm, and other vagaries of nature.

These are made of out of galvanized steel, which gives adequate tensional strength to support the weight of conductors onto the perfect positions. Suspension clamps feature a clever ergonomic design that ensures that the weight of the conductor is evenly distributed on the clamp’s body. This design also provides perfect angles of connection for the conductor.

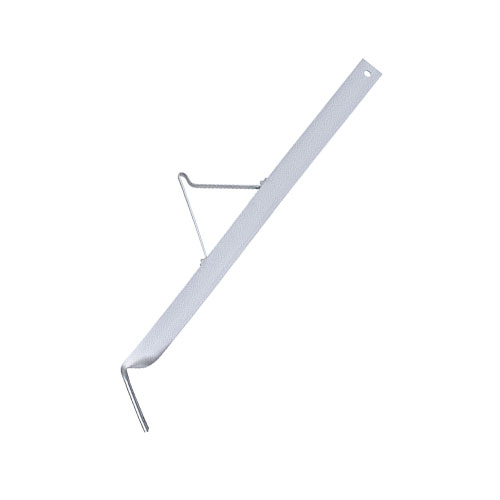

The V Crossarm Brace is a type of Pole Line Hardware used to provide additional support to a wooden utility pole. It is designed to be installed at a 45-degree angle between the pole and the crossarm, forming a V shape. The brace is typically made of galvanized steel or aluminum and is available in various sizes to fit different pole and crossarm configurations.

It is used to support heavy crossarms on utility poles. Brace are fastened to the pole with a 5/8 inch bolt, mounts to underside of crossarm with 1/2 inch bolts or lag Screws. Hot dip galvanized meet ASTM A153 specification.

Yoke plate is a type of string hardware used for coupling the electrical clevis and the insulators or the socket tongue on the transmission line. During the yoke plate installation process, the insulators that are connected to the cross arm will be on one side and the conductor termination is on the other side.

It can be made of carbon steel, ductile iron, forged steel or aluminum alloy and is hot dip galvanized. When it comes to the construction, a yoke plate is usually made high-grade steel carbon. This material is relatively thick enough to give it enough strength. The tensile strength of the material shields it from breaking of undergoing structural damage. The powerline fitting is designed to have a high rated breaking strength (RBS).

For the design, the most common shape of the yoke plate is the triangular yoke plate. This shape is considered universal as it can easily fit into a wide range of applications.

Copyright © 2025 Pinnacle Engineering & Exporters. All Rights Reserved